Breadcrumbs

Liquid Cooling - Tubing and Fittings

Understanding key components of your liquid cooling system.

There are several components to a liquid cooling system, but having the right tubing and fittings is very important no matter what other components you choose.

Types of tubing:

Tubing can be broken down into two categories - flexible tubing (also referred to as soft tubing) and rigid tubing (also referred to as hard tubing). What is significant about the tubing choice is that different fittings are needed depending on whether you are using flexible tubing or rigid tubing.

Flexible tubing is softer by design to make it easier to work with inside your computer case. Flexible tubing might be rubber, silicone, neoprene, or other softer designs, and it may be clear, colored, or opaque. Designed for liquid cooling, flexible tubing can bend and flex without kinking, and will stand up to flowing liquids. Proper flexible tubing is also designed with considerations toward adding colors to the coolant as well as preventing fogging in clear tubes. A sub-standard tubing could allow for undesirable appearance, functionality, or even leaks within your system. Flexible tubing requires specifically designed fittings.

Rigid tubing is hard by design, but it can be bent and shaped, or cut and connected, to fit the project. These tasks could require special tools depending on the project. Rigid tubing might be made of materials like plexiglass or other hard acrylic materials or could even be brass tubing with a chrome finish. Rigid tubing tends to be more challenging to work with, but some feel that the result gives a nice appearance to the project. Rigid tubing requires specifically designed fittings.

How tubing and fittings are measured:

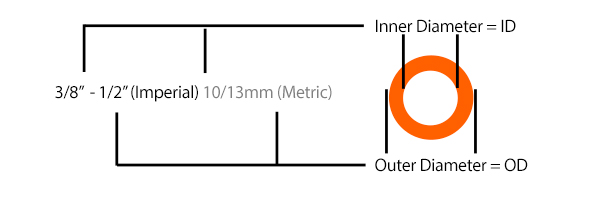

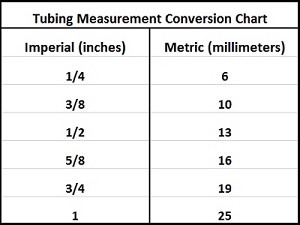

It’s extremely important to match measurements of tubing with fittings – even the slightest mismatch could cause your system to leak, damaging your components. There are two types of measurements to understand: Outer diameter, also referred to as OD, is the precise size of the outside of the tubing. This will always be the larger measurement of the two. Inner diameter, also referred to as ID, is the precise size of the inside of the tubing. The OD and the ID of the tubing and the fittings must match properly with each other. Finally, it is common to find tubing and fitting measurements referenced in either metric terms (millimeters) or in imperial terms (inches) – how they are measured only matters to the extent that they match each other properly.

Types of fittings:

The type of fittings used is determined by the type of tubing selected, or vice versa. There are two types of fittings designed for flexible tubing, and a different type of fitting along with a second variation designed for rigid tubing. Choose only the type of fitting and tubing designed to be compatible with each other.

Barbed fittings tend to be the least expensive and most simple fittings designed for use with flexible tubing. Barbed fittings will identify measurements by the Inner Diameter (ID) only. They work by simply inserting the barbed fitting into the properly matched sized tubing. It is strongly recommended, though not required, to use some type of clamp to secure the tubing to the barbed fitting.

Compression fittings are a popular approach for use with flexible tubing. Compression fittings tend to cost a little more than barbed fittings, but many believe they offer a better appearance – they also require a little more effort to ensure that they are properly installed and connected. Compression fittings identify measurements by both the Inner Diameter (ID) and the Outer Diameter (OD). Once again, it is extremely important that both measurements match exactly between the tubing and the fitting. Compression fittings work by inserting the tube through the locking ring and then the base part of the fitting into the tube - just like a barbed fitting. The locking ring is then tightened over the tubing to the threaded base, compressing and securing the connection at that point.

Push-in fittings are designed for use with rigid tubing. The push-in fitting is a single base with two O-rings, and you simply push the tubing into the fitting to make a seal.

The Compression fitting for rigid tubing works similarly to the process for flexible tubing, however Compression fittings for rigid tubing have two O-rings, one in the base and a second one in the locking ring. Just like the compression fittings designed for flexible tubing, these tend to cost a little more than push in fittings, but are perceived as more aesthetically pleasing and more secure.

A few additional important points:

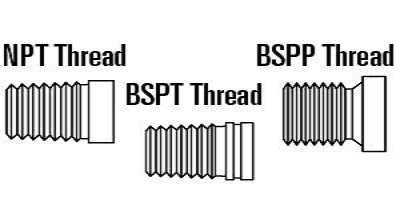

Thread size is another measurement to be aware of with fittings. Most fittings use a standard 12.9mm thread size known as G1/4” (or 12.9 mm) but some older fittings used other sizes. It is very important for the thread size of your fittings to match up, or your system will inevitably leak. When considering threaded fittings, it is also important to use compatible thread types in order to securely seal the connection and prevent the possibility of leaks.

NPT refers to National Pipe Thread and is the most common type of thread used in the United States. Because it is slightly tapered it is a more secure seal that is less likely to leak than other types.

BSPT or British Standard Pipe Thread has similar characteristics to NPT, but this variation is more common in places like China and Japan.

BSPP is British Standard Parallel Pipe Thread, most used in Europe, the UK, and other places. The main difference with this one is that the threaded connection is not tapered.

Water flow is also something to be considered. Larger tubing does not necessarily equate to more water flow. Manage the water flow through your system by using your water pump configuration. Other components in your system could also have a direct impact on the water flow rate.

To Summarize:

- Tubing and fittings are a key component of your liquid cooling system

- Tubing can be either soft and flexible or hard and rigid

- It is extremely important to have the right type and size fittings for the type of tubing used

- A project like this can be as basic and simple or as fancy and complex as you want to make it

This article is part of a multi part series.

Liquid Cooling - Water Blocks Radiators and Fans can be found here.

Liquid Cooling - Coolants Reservoirs and Pumps can be found here.

Liquid Cooling - Process and Terms can be found here.

Technical Support Community

Free technical support is available for your desktops, laptops, printers, software usage and more, via our new community forum, where our tech support staff, or the Micro Center Community will be happy to answer your questions online.

Forums

Ask questions and get answers from our technical support team or our community.

PC Builds

Help in Choosing Parts

Troubleshooting